-

+8615890068607

+8615890068607

-

bella@nanbei-china.com

bella@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

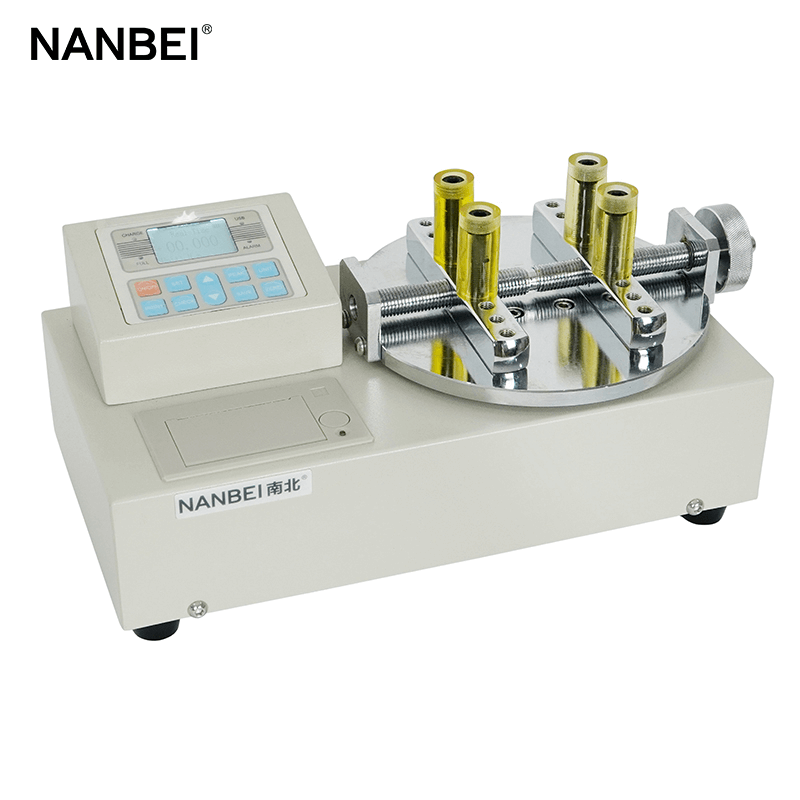

Torque meter is a kind of quality control equipment, which can be used for calibration of torque sensor, and testing of transmission torque of power system as well as tightening torque of bolts and other fasteners.

Structure and components of torque tester:

1. Torque sensor

The torque sensor is an electronic device similar to a loader, which is mainly used to convert the measured torque value into the torque of an electrical signal. The electrical signal is usually output between several millivolts, so it can be used only after being amplified by the instrument amplifier. Torque sensors generally include rotary, fixed reactive and embedded types for calibration and audit purposes.

2. Digital display

A key component of modern torque meter is digital display. The digital display is used to detect the output signal of the sensor and calculate and display the torque value on the screen. In most cases, the display and sensor are connected as a whole, which is called "desktop torque meter". External rotary and fixed sensors can be used for portable displays (hand-held torque meters).

Digital torque meter is used to check and study the torque required for the assembly of small parts, such as measuring the torque of industrial products such as screws and bottle caps, and checking whether the products are qualified.

Previous: No Information