-

+8615890068607

+8615890068607

-

bella@nanbei-china.com

bella@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

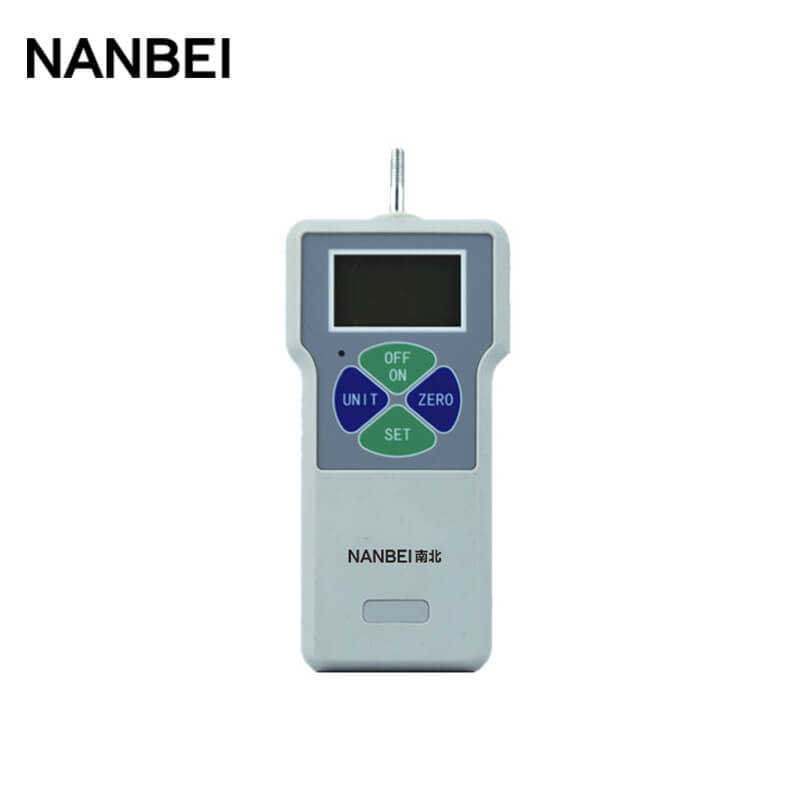

The digital force gauge is made with modern electronic sensor technology, and adopts strain-type electronic sensors for measurement, with relatively high accuracy, which has the characteristics of easy portability, high precision and long service life. The push-pull dynamometer sometimes has abnormal displacement in normal use. So, how do we solve the displacement failure?

Push pull force gauge displacement troubleshooting method:

1. After eliminating the fault of the displacement sensor, check whether the amplifier unit is normal.

2. First disconnect the output signal of the amplifier unit, remove the output wiring, add a DC input signal to the amplifier unit by the push-pull force gauge meter through the workstation, and measure the input condition of the amplifier unit, repeat several times, if the output signal changes linearly, then the amplifier unit is normal.

3. If there is no problem in the above two steps, it may be a system setting problem.

4. Check the displayed data in the work and compare it with the normal data. After the digital dynamometer is found to be abnormal, reset the stroke of the actuator.

5. If the display value of the push-pull gauge on the display panel of the workstation is still incorrect, re-calibrate the displacement system.

Force gauge is a mechanical measuring instrument used for push and pull tests. The push-pull force gauge is suitable for push-pull load force testing of electronic appliances, light industrial textiles, construction hardware, lighters and ignition devices, fire-fighting equipment, pen-making, lock-making, fishing gear, power machinery, scientific research institutions and other industries.

Previous: No Information