-

+8615890068607

+8615890068607

-

bella@nanbei-china.com

bella@nanbei-china.com

Mobile:+86 15890068607

Mobile:+86 15890068607

NANBEI ADN Dynamic Torque Tester

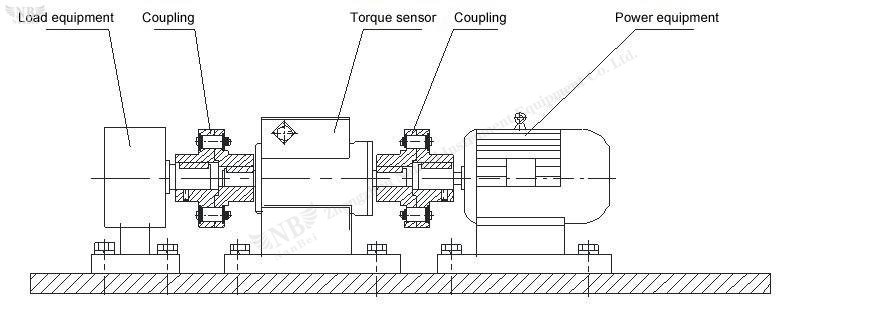

Installation drawing of torque tester:

1, Measuring the height of sensor's diameter of axle and center, waiting.

2, Using two groups of coupling, installed the sensor between the power equipment and load.

3,Adjusted the center height and coaxiality of load, power equipment and sensors respectively, and then fixed it,

and reliable fastening, are not allowed to have loosening.

4, You can choose the rigid or flexibility coupling. In the circumstances of great vibration or the coaxiality is

larger than 0.05 mm, it's better to choose flexible couplings.

5, The installed mesa should have certain strength.

6, The coupling should rely on the shoulder in both ends of the sensor.

Special attention to of torque tester

1:The requirements of Installation environment:

2:Temperature: - 10 °c ~ 60 °c

3:Humidity: < 90% RH

4:No inflammable, explosive

5:When installation, don't knock and collide sensor.

6:Prohibit charged operation when installing.

7:The sensor is not waterproof, explosion-proof design, pay attention when using.

8:Avoid strong interference, and ensure the normal operation of the equipment.